3d & Product Development

16oz “Christopher” Latte Mug

Target – Room Essentials – Spring 2021

Role: Senior Product Development Specialist

Summary: Designed and managed the full product development cycle—from concept and CAD modeling to virtual prototyping, sampling, factory coordination, and final production for the 16oz “Christopher” Latte Mug. Utilized Adobe CC, Solidworks, KeyShot, and 3Ds Max.

Target sought a fresh mug design for their spring Room Essentials program, which also included Father’s Day. I saw an opportunity to solve a personal frustration—mug handles that never quite fit my hand. I knew I wasn’t alone, so I set out to design a handle that comfortably accommodated larger hands while maintaining a sleek, modern form.

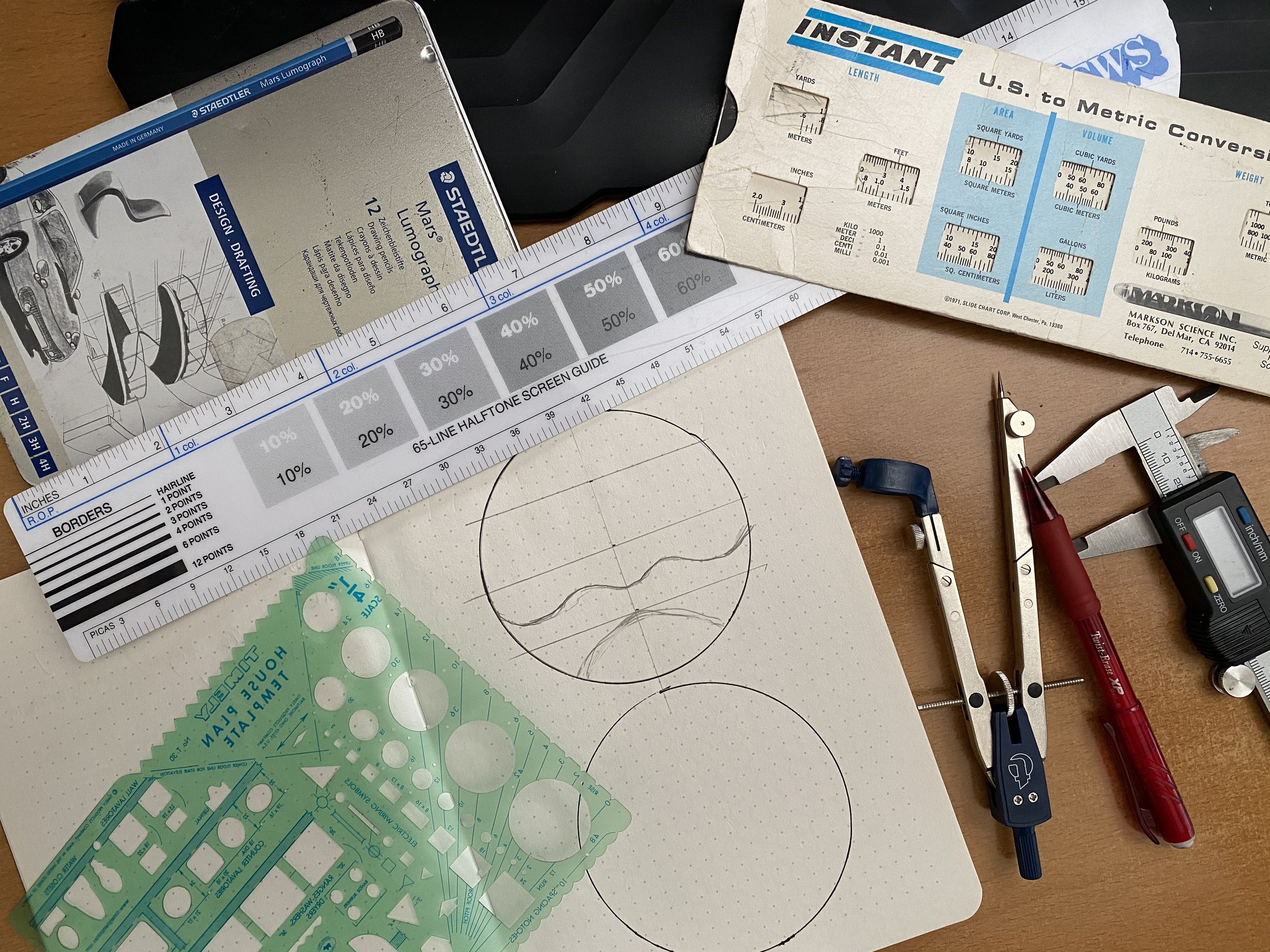

Since most Target mugs require a minimum 16oz capacity, ensuring the design met this standard was a key early step. Using Solidworks, I shaped the form while continuously checking volume. I also surveyed a range of hand sizes to refine the handle’s dimensions, balancing function with aesthetics for a visually appealing, ergonomic design.

Once the form was approved, I created a detailed SRF (Sample Request Form) with precise measurements and instructions for the factory to produce an initial prototype. After rounds of adjustments, a final mold was made—bringing the design one step closer to production.

Virtual Development played a crucial role in the process. Using KeyShot, I applied CMF (Color, Material, and Finish) and graphics from our Creative Team to create realistic renderings. This allowed for faster approvals and reduced reliance on physical samples, streamlining the timeline.

With the final assortment approved, it was off to the factory. We created a detailed spec sheet for each mug, including CMF instructions, artwork application, and production details to ensure accuracy.

Seeing my design in stores for the first time was an unforgettable moment—but even more rewarding was receiving photos from friends and family across the country, proudly picking up my namesake mug.

Finally, the “Christopher” Latte Mug hit Target shelves nationwide!

Outstanding comfort.

This mug quickly became my go-to. And with a 100% sell-through on multiple versions and over 75% sell-through on the rest, it became a favorite for many others, too.

15oz “CJ” Mustache Mug – Father’s Day

A modern take on a forgotten “technological advancement.” The Mustache Mug is said to have been invented in the 1870s, designed to keep facial hair while drinking. With beards and mustaches making a strong comeback, I saw an opportunity to reintroduce this classic concept. Inspired by an antique teacup passed down from my Great Aunt Avis, I brought the design into the 21st century—blending vintage charm with contemporary function.

Antique Teacup Inspiration

Mustache Guard Concept Sketches

Sample of final product

Artwork Designed for Father’s Day

Mockups of Father’a Day Artwork on CJ Mustache Mug + Other Shapes

3D Prototyping & Mapping Patterns for Soft-Touch (Haptic) Textured Tumblers

The science of touch—Haptics—has always fascinated me. Did you know that simply picking up an item in a store makes you 30%–62% more likely to buy it? This psychological phenomenon, known as the Endowment Effect, creates a sense of ownership through touch. With this in mind, I designed tumblers featuring soft-touch coatings and textured patterns, ensuring that once someone held them, they’d feel an immediate connection.

3D prototyping was a brand-new practice for PMI & FCG. By quickly mocking up ideas in 3D, we could visualize products in real-world form, allowing for faster iteration and cutting our R&D timeline from weeks to mere hours.

Patterns were converted into normal maps, which were then applied to 3D tumbler models to test texture placement and accuracy.

Problem: Pattern details were often misinterpreted when sent to the factory, leading to production delays.

Solution: I developed a Standard Operating Procedure (SOP) that included an additional pop-out diagram highlighting the profile of each individual pattern element. This simple yet effective adjustment eliminated 98% of factory misinterpretations, drastically reducing back-and-forth communication and saving multiple days on every project.

Miscellaneous CADs, 3D Prototypes & Personal Photos